STOP PRESS! This project is now revised and updated here, and will now create KML files, to open directly in google earth!

Now, my friend Julian and I have, for the past three years, been building a racing car. I've been lending a hand with the electrics and certain mechanical bits.

It's based on a 1971 Mini Clubman (by the name of Florence)

Here's Julian, fitting the door mirror.

After it's first season competing (with Julian at the wheel) , it's not disgraced itself at a few hillclimbs...

This video isn't mine, but this is Julian at the National Championship at Wiscombe Park late last year.

Anyway. Julian wants a bit more power, this has necessitated a new and bigger engine, and a new and bigger carburetor. In turn, the baulkhead had to be modified to accommodate the changes. Now the lovely dashboard we had created to house the instruments had to face some changes, and the large mechanical speedo had to go (when you're racing, you're not looking at how fast you're going!)

We looked for a small speedo that would suit our requirements, but I mooted the idea of a digital speedo, collecting it's data from a GPS receiver... I have previously used U-blox receivers and chipsets commercially, so I ordered one from the lovely people at Hobby Components here.

Excellent. Provides updates at up to 5 times per second.

Now, this coupled to an Arduino pro-mini, and a nice OLED display would provide a nice speedo...

The display is a 128x64 SDD1306 OLED display, and was purchased from eBay.

Then I got to thinking ... what if I could log some data to an SD card as well... might provide some interesting data for when the car is racing. So I ordered an SD card reader at the same time ...

eBay is once again our friend!

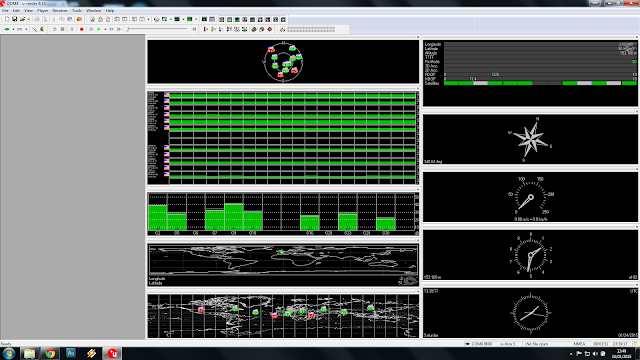

Now first things first, we need to configure our GPS receiver. This is done by hooking up the receiver board to our PC (I used the same FTDI converter I use to program the Pro-mini boards).

Go and get yourself a copy of uCenter from the U Blox website here.

Now when the software opens, you will need to tell it which com port and baud rate the receiver is on. Click on the receiver tab, and select the com port. Try 9600 for the baud rate, if you see no data, try another speed. Soon enough you should see some data from the receiver.

Amazing, isn't it!

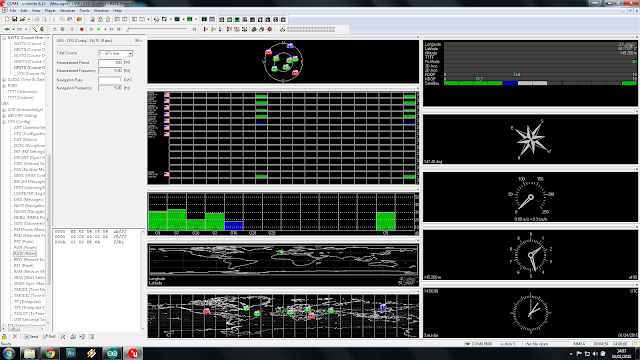

Now click View and Messages View. Maximise the messages window.

Now scroll down to UBX and click it to expand the tree. Click on CFG . Now click on RATES and change the Measurement Period to 200mS.

Now expand the PORTS section, and change the baudrate to 57600. Once you do this, uCenter will lose communications with the receiver module. Go to Receiver, and re-set the baudrate to 57600.

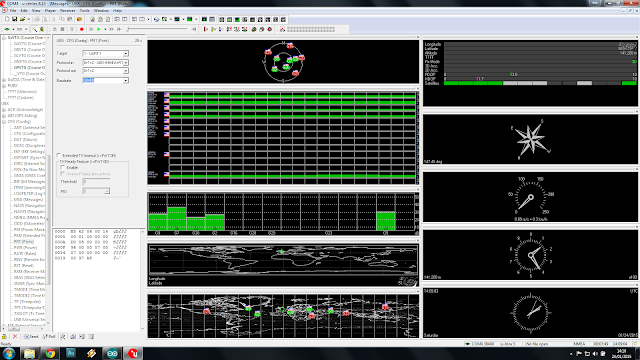

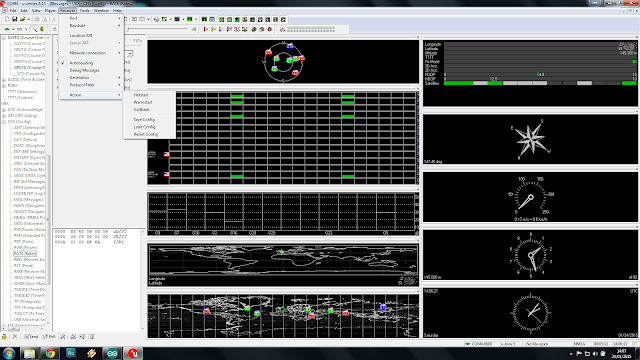

Now click on Receiver again, selection Action and click Save Config.

You can now disconnect the receiver from the PC.

Now, a word about power. The uBlox receiver is happy at 3.3 or 5v, The Pro-mini I've got is good at 3.3v or 5v, the display works great on 3.3v or 5v... the SD Card reader, whilst it has a pin marked 5v, is only happy with 3.3v on it's data and clock pins. The 5v is purely to power the on-board 3.3v regulator. Now, we can either run everything from 5v and use a level converter between the arduino and the SD card reader (stupid) , or we can use the 3.3v from the card reader's on board reg to drive everything else (a really good idea!)

So, from the car our 12v is dropped to 5v using an ordinary 7805 voltage regulator, this is then supplied to the SD Card reader. The 3.3V pin on the card reader then supplies power to the arduino, the GPS receiver and the display.

SDA on the display is connected to A4, SDC to A5. The SD card interface is connected to pins 4 (CS), 11 (MOSI), 12 (MISO) & 13 (SCK).

A toggle switch is connected between pin 9 and ground. The toggle switch is used to switch on and off the logging feature.

The GPS receiver's TX pin is simply coupled to the hardware RX pin on the arduino, but not until we've uploaded the software!

Now there is an excellent library to control the display from Adafruit, but it is very memory intensive, and somewhat slow. This caused difficulty in writing to the SD card in time.

After spending a while surfing, I happened upon a lightweight library at http://blog.oscarliang.net/arduino-oled-display-library/ which is perfect, although it's not designed for this display. There's a requirement to enable the on-board inverter in our sketch.

We'll also need the most excellent TinyGPSPlus library from https://github.com/mikalhart/TinyGPSPlus

The SD card will need to be formatted on your Windows PC as FAT32. Open notepad and save a blank file as gps.txt to the card.

Here's the schematic:-

You will notice there's a zener diode before the 7805, this to clamp any nasties that might be present on our 12V supply from the vehicle (usually on cranking). Any value between 18 and 32 volts will do.

Lashed up for testing...

7805 power supply.

7805 power supply.Will it all fit in the box?

Of course ;)

Painted black to match the dash.

Not many satellites being received on the bench!

But a few in the window!

The receiver is actually very sensitive, although initial lock may take a few minutes, once recent data is stored in the receiver's non-volatile memory, warm starts are very quick indeed.

Out for a quick test run, and logged some data....

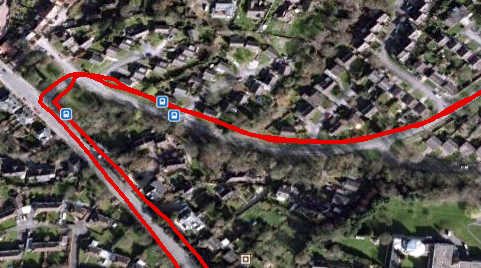

It's pretty easy to import the txt file into google maps, and get some useful data...

It's pretty easy to import the txt file into google maps, and get some useful data...Here, individual data points are shown, each showing the speed at that point.

Anyway, here's the sketch....

/* Fast GPS data logger. (c) 14th February 2015 A.G.Doswell Released to all and sundry under GNU License. The sketch uses a U-Blox 6M GPS satellite module connected to the hardware serial interface, a 128x64 SDD1306 OLED display module connected as an I2C device to pins A4 (SDA)& A5 (SCL) and an SD card interface connected to pins 4 (CS), 11 (MOSI), 12 (MISO) & 13 (SCK) The arduino used is a Nano with 3.3v ATMEGA328P. Warning - Many SD card interfaces are not 5V. There's a toggle switch which connects pin 9 to GND for Record. Data is written to the card an impressive 4 times per second, in real-time. The OzOled library is not quite "right" for this application, but works, and is lightweight and fast enough. Thanks Oscar! It is available here : http://blog.oscarliang.net/arduino-oled-display-library/ TinyGPSPlus is available here :https://github.com/mikalhart/TinyGPSPlus */ #include <SPI.h> #include <Wire.h> #include <OzOLED.h> #include <TinyGPS++.h> #include <SD.h> static const uint32_t GPSBaud = 57600; int SatVal; // Number of satellites locked int Speed; // Speed in MPH char SpeedA [4]; // Speed as char TinyGPSPlus gps; // Feed gps data to TinySGPSPlus File myFile; // Start SD int speedDigit; // Number of digits in Speedo display boolean card; // Is there a card present? boolean rec = false; // Is the record switch low? (false = high) int recPin = 9; // Record pin (Pull low to record data) void setup() { Serial.begin(GPSBaud); // Start GPS serial comms pinMode (recPin, INPUT_PULLUP); // recPin as input and pulled high OzOled.init(); // initialze SDD1306 OLED display OzOled.sendCommand(0x8d); // Set displays inbuilt inverter on OzOled.sendCommand(0x14); OzOled.setBrightness(0xFF); // ... and brightness to max OzOled.clearDisplay(); // Clear the screen OzOled.setNormalDisplay(); // Set display to Normal mode pinMode(10, OUTPUT); // CS for SD card, wether it likes it, or not. OzOled.clearDisplay(); if (!SD.begin(4)) { //Check SD card is present OzOled.printString("SD card fail ",0,7); card = false; } else { OzOled.printString("SD card OK ",0,7); card = true; } OzOled.printString("Sats:",0,0); // Set up display OzOled.printString("Speed:",0,1); OzOled.printString("MPH",7,6); } void loop() { while (Serial.available() > 0) //While GPS message received if (gps.encode(Serial.read())) displayInfo(); } void displayInfo() { // Display the data SatVal = int(gps.satellites.value()); Speed = int(gps.speed.mph()); itoa (Speed,SpeedA,10); OzOled.printNumber ((long)SatVal,6,0); OzOled.printBigNumber (SpeedA, 7,1); speedDigit = strlen(SpeedA); // get length of Speed , and delete left behind zero if req'd if (speedDigit == 1) OzOled.printBigNumber(" ",10,1); if (digitalRead(recPin) == HIGH && card == true) { //If the record switch is high and the card is OK, write card data rec = true; OzOled.printString("SD card OK REC",0,7); } if (digitalRead(recPin) == LOW && card == true) { rec = false; OzOled.printString("SD card OK ",0,7); } if (card==true && rec==true) { writeInfo(); //write the data to the SD card } smartDelay(200); } // This custom version of delay() ensures that the gps object // is being "fed". static void smartDelay(unsigned long ms) { unsigned long start = millis(); do { while (Serial.available()) gps.encode(Serial.read()); } while (millis() - start < ms); } void writeInfo() { //Write the data to the SD card Date,Time,Lat,Long,Spped (MPH) and number of satellites locked myFile = SD.open("gps.txt", FILE_WRITE); if (myFile) { myFile.print(gps.date.month()); myFile.print(F("/")); myFile.print(gps.date.day()); myFile.print(F("/")); myFile.print(gps.date.year()); myFile.print(F(",")); if (gps.time.hour() < 10) myFile.print(F("0")); myFile.print(gps.time.hour()); myFile.print(F(":")); if (gps.time.minute() < 10) myFile.print(F("0")); myFile.print(gps.time.minute()); myFile.print(F(":")); if (gps.time.second() < 10) myFile.print(F("0")); myFile.print(gps.time.second()); myFile.print(F(",")); myFile.print(gps.location.lat(), 6); myFile.print(F(",")); myFile.print(gps.location.lng(), 6); myFile.print(F(",")); myFile.print(gps.speed.mph(),1); myFile.print(F(",")); myFile.println(gps.satellites.value()); // close the file: myFile.close(); } }