Enter Frank C's Hedghog converter...

Details of the project an be found here.. http://electronics.frankcuffe.ovh/hedghog

It's a stunning project, and features a few useful functions not found on my other standards converter, the Aurora SCRF405 (which for those of you who don't fancy the DIY approach, can be found here http://www.tech-retro.com/Aurora_Design/Single_Converter.html)

It consists of a digital video converter (The TVP5150) which converts PAL to an 8-bit ITU−R BT.656 format. These one's and zero's are fed to an EP2C5 FPGA development board, which mounts to the top of the PCB. The magic happens in here, and the resultant 405 line system A video output emerges from the resistor ladder DAC. This is then passed to a MC44BS373 modulator IC, which is tunable on all Band I and Band III channels. The tuning of the modulator is also taken care of within the FPGA, and is set with a hex switch. There's a second MC44BS373 which is modulating audio at the required 3.5MHZ spacing below the vision carrier.

The unit produces aspect ratios of both 4:3 and 5:4 (5:4 being in use up to 1950)

There's a Pedestal function which lifts black level 50 mV above blanking level. This was abandoned on transmitters post-war, as it reduced the efficiency of the transmitters. It may help with early sets that suffer from flyback lines.

You can select between normal broad pulses or broad pulses with equalising pulses. Equalising pulses were never in the spec, although it may help interlace on some sets (ironically it upsets interlace on some, and causes the top of the picture on some Bush sets to "hook")

The three-line interpolator has three settings: soft, medium and sharp interpolation apertures.

Switchable 1KHz or 400Hz test tones.

There's also a PM5544'esque test pattern, and stair-steps.

These functions are all available via switches on the front panel.

PCBs were ordered from the most-excellent pcbway.com, and arrived within 7 days.

PCBs were ordered from the most-excellent pcbway.com, and arrived within 7 days.The FPGA board came from eBay.

The MC44BS373's I had to source from AliExpress, as it's now classed as obsolete, however, at the time of writing this, there appears to be plenty of stock from "grey" suppliers. I dislike doing this, as many times I have been caught out with fake parts! Caveat Emptor. I used the AliExpress supplier YT Electronics components co.,ltd

The phono sockets also came from AliExpress (link) and fit with a minor modification.

Assembly is straight forward, don't let the surface mount put you off. Get a decent quality gel flux. If you've seen my videos, you may have realised I suffer with a benign tremor (nothing to worry about, I've had it since I was 14), and I can mount this stuff with ease. I do have the advantage of a microscope.

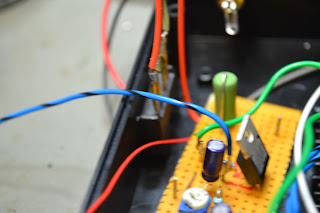

A bit of blue-tac helps hold the board in place. First off I fit the semi's.

Then the passives...

Programming the FPGA is straight-forward in windows, using the Quartus II (13.0 sp1) software, and the "USB-blaster" supplied with the FPGA board. I failed to get the software to work under Ubuntu (although it would "see" the programmer hardware, the program option remained unavailable). When correctly programmed, there's a binary counter running on three LEDs on the board.

Sockets and switches are mounted.

And the FPGA board fitted.

... and it's switched on!

However, some fault finding was required, as although the test patterns and test tones were OK, there was no converted video. With the help of the designer, Frank and the VRAT forum (here), it was apparent something was wrong with my FPGA board. After some fault-finding, a tiny solder bridge was found on the FPGA board, shorting out two of the lines. Once this was removed, the converter worked faultlessly.

Moire pattern is being caused by the camera, the actual picture quality is superb.

I like the additional functions available from the front panel. Picture quality appears to be on a par with the aurora converter.

What I'd really like is a centre-cut out function for dealing with a 16:9 input.... Frank?