It's a pair of 460KHz Crystals in a standard B7G glass valve envelope. Pretty.

It's sat on my desk for months ... I keep looking at it, and wondering what to do with it...

About the same time, my mate Alan gave me a small CRT video monitor.

About the same time, my mate Alan gave me a small CRT video monitor.

I think it's come from a reversing camera from a lorry...

After working out the power pins on the rear, it springs into life, and a stupid plan is hatched....

Take the crystal, and build a CD 4060 oscillator/ripple counter, divide the output down to produce ~28Hz (460000/16384). Feed the 28Hz into an Arduino interrupt pin, and get it to run a clock. Run the TV out library as well, and produce an image on the screen. Brilliant. Stupid. All in one go.

Now, with a crystal oscillator, we need to know the crystal's "load" capacitance. This is formed by the two capacitors off each crystal leg to ground. Every crystal needs these. Get it wrong, and it's unlikely to reliably oscillate (if it does at all). For example, the usual Arduino crystal of 16MHz needs about 22pF on each leg to reliably start up. We'll also need to bias the 4060 so it always starts. Regular readers of this blog will know I used to include a 1 megohm resistor (unnecessarily) across the arduino crystal in my stand-alone designs. We'll need this in our oscillator. (We didn't in the ATMega328 because the bias is supplied by the IC). We'll also need a load resistor. The load resistor is there to make sure there's a voltage on the crystal with which to start the oscillation.

The issue we have is we have no idea of the load capacitance required, or it's required load resistor. There's a rule of thumb about load resistors. 1mm thickness of crystal = 1K ... our crystal is a little over 1mm thick, let's opt for 2.2K. Capacitance? No such rule of thumb. I was going to put 2 adjustable 100pF capacitors in each leg, and twiddle until it would reliably start. Sadly, I could only find one 100pF capacitor... so that went in one leg, and a 22pF fixed capacitor on the other.

Result? Nothing. No amount of twiddling of the 100pF capacitor helped. OK, add another 22pF capacitor to the circuit to give 44pF ... and it's oscillating, but it frequency isn't stable. Remove the two 22pF capacitors and replace with 100pF ....

... and bingo! ... 28.061 Hz pops out of the Q14 pin. It's reliable and steady as a rock. It's a shade off frequency, but crystals do tend to drfit with age, and I doubt my load capacitance quite meets the original spec. It should be 28.076171875Hz.. (460000/16384)

It's all built "fugly" style on a bit of perf board.

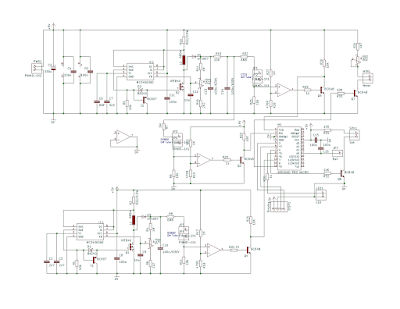

Here's the circuit

The pulses are fed into an Arduino Uno which allows a bit of development to go on, and a discovery is made (should have read the read.me!) .... you can't use an interrupt when using the TVout library, as the interrupts are being used to generate the timing need for video ... no problem, we'll use another arduino to generate the video and pass the data to it over a serial interface..

Now Arduino no1 is just doing the final bit of dividing down and outputting seconds over it's hardware serial interface, it's given it's own 16MHz crystal and mounted on the perfboard along with a 7805 to provide the 5V. The Arduino Uno is now used to develop the video software.

Now Arduino no1 is just doing the final bit of dividing down and outputting seconds over it's hardware serial interface, it's given it's own 16MHz crystal and mounted on the perfboard along with a 7805 to provide the 5V. The Arduino Uno is now used to develop the video software.

Before long, we have a rather nice clock display running.... (The photo doesn't do it justice, this is the tiny colour monitor I use in the workshop, and the photograph has artifacts..) . There's still plenty of memory left though ....

How about an animated "Pong" (Copyright Atari, the dawn of time) clock? Oh this is getting silly... Yeah, OK...

There appears a number of Arduino "pong" clones on the web, that will (allegedly) sit happily with TVout. After trying, I can't find one that works properly. Shoddy ball/bat collision (it's at best hit and miss 🤣), the ball flying right through the bat half the time.. we don't want that, so I re-engineered the code to suit.

Next thing... We don't want the monitor on all the time, consuming power and wearing the CRT cathode out. So some means of switching on the monitor when someone maybe looking at it. I did contemplate using a passive infrared sensor (PIR), but that's overkill. A simple sound detector will do. We can implement this on Arduino 1.

A small electret microphone is amplified using an op-amp, and the output fed to Arduino 1's A0 pin.

This input is measured a few times, averaged, and compared to a value. There's an interesting bit of code here, whereby the audio is "rectified" in software, this means any negative audio is "flipped" over, and a negative peak has the same value as a positive one (I've got a cunning plan for this bit of code, watch this space...). Anyway if this level increases above a certain point, there's some noise about, and we can switch our monitor on.

This input is measured a few times, averaged, and compared to a value. There's an interesting bit of code here, whereby the audio is "rectified" in software, this means any negative audio is "flipped" over, and a negative peak has the same value as a positive one (I've got a cunning plan for this bit of code, watch this space...). Anyway if this level increases above a certain point, there's some noise about, and we can switch our monitor on.

The output pin feeds a BC547 transistor, which in turn switches on a P-channel FET as a high-side driver, which supplies 12V to the monitor. A minimum on time is specified, as the monitor takes 8 seconds for the CRT cathode to warm. Even with the monitor off, Arduino 2 is still doing it's thing and creating the video waveforms and dealing with time.

This is connected to A0 of Arduino 2. It's just a cheap 10K NTC thermistor.

Meanwhile, we need a method for setting the clock. 3 push buttons are added, one for hours, one for mins and one for set, and connected to Arduino 2. When Arduino 2 starts up, it automatically enters this screen, and the hours and minutes can be set with the buttons. Once the set button is pressed, a reset pulse is sent to Arduino 1, and it's restarted, setting the seconds back to zero.

Meanwhile, we need a method for setting the clock. 3 push buttons are added, one for hours, one for mins and one for set, and connected to Arduino 2. When Arduino 2 starts up, it automatically enters this screen, and the hours and minutes can be set with the buttons. Once the set button is pressed, a reset pulse is sent to Arduino 1, and it's restarted, setting the seconds back to zero.

I also added a bit of code to enable easy calibration of the clock. Grounding pin D6 (pin 12 on the actual microcontroller) puts Arduino 1 into a calibration mode, whereby it outputs minutes elapsed since start-up and seconds over the serial interface. Disconnect Arduino 2, and connect Arduino 1 to an FTDI converter and monitor the serial output. Open the arduino monitor , and enable time stamp. Write down the time the sketch started, and the difference between that and the current elapsed time. Leave it for hours, then calculate how far it's drifted and use this value to alter the calibration value in Arduino 1 (old cal factor * ( number of seconds expected / number of seconds counted) . Excellent, it now keeps good time.

Excellent ... what about a chime?

I don't want just a beep or something from the micro... I'd like a proper chime.

A small solenoid is purchased from eBay...

...and a bicycle bell...

... and a driver circuit created to be driven from Arduino 2.

So the final thing looks like this ...

So the final thing looks like this ...The vintage crystal is top left, with the 14 bit ripple counter to it's right, and the 7805 voltage regaultor to the right of that. The horizontal ATMEGA328P is our seconds generator, and controls the power to the monitor, the microphone and amplifier can be seen just below it. The high side FET is there too, and runs very cool, as the monitor draws about ~520mA when running. The vertical ATMEGA is creating the video, and also drives the chime, via the low side FET under the stripey ribbon cable, which leads off to the three push buttons, hours, minutes and set. Video is connected to the monitor via the small coax just above the ATMEGA.

The final schematic.

The clock display itself has three modes.

Clock ...

... pong ...

... pong ... ... and 3D cube ...

... and 3D cube ...

The software can be found, as usual, on my github page https://github.com/andydoswell/stupid-video-clock , and I've included the TV out library as well, as I've modified it so it compiles without issue, has a "degrees" symbol and tweaked the timing a shade.

Now, I'd better start thinking about a case for it... some sort of perspex thing?

My colleague , Alan, has given it a good name... "Well, it goes "ping", and plays "pong" ... it's the ping-pong clock" 😁